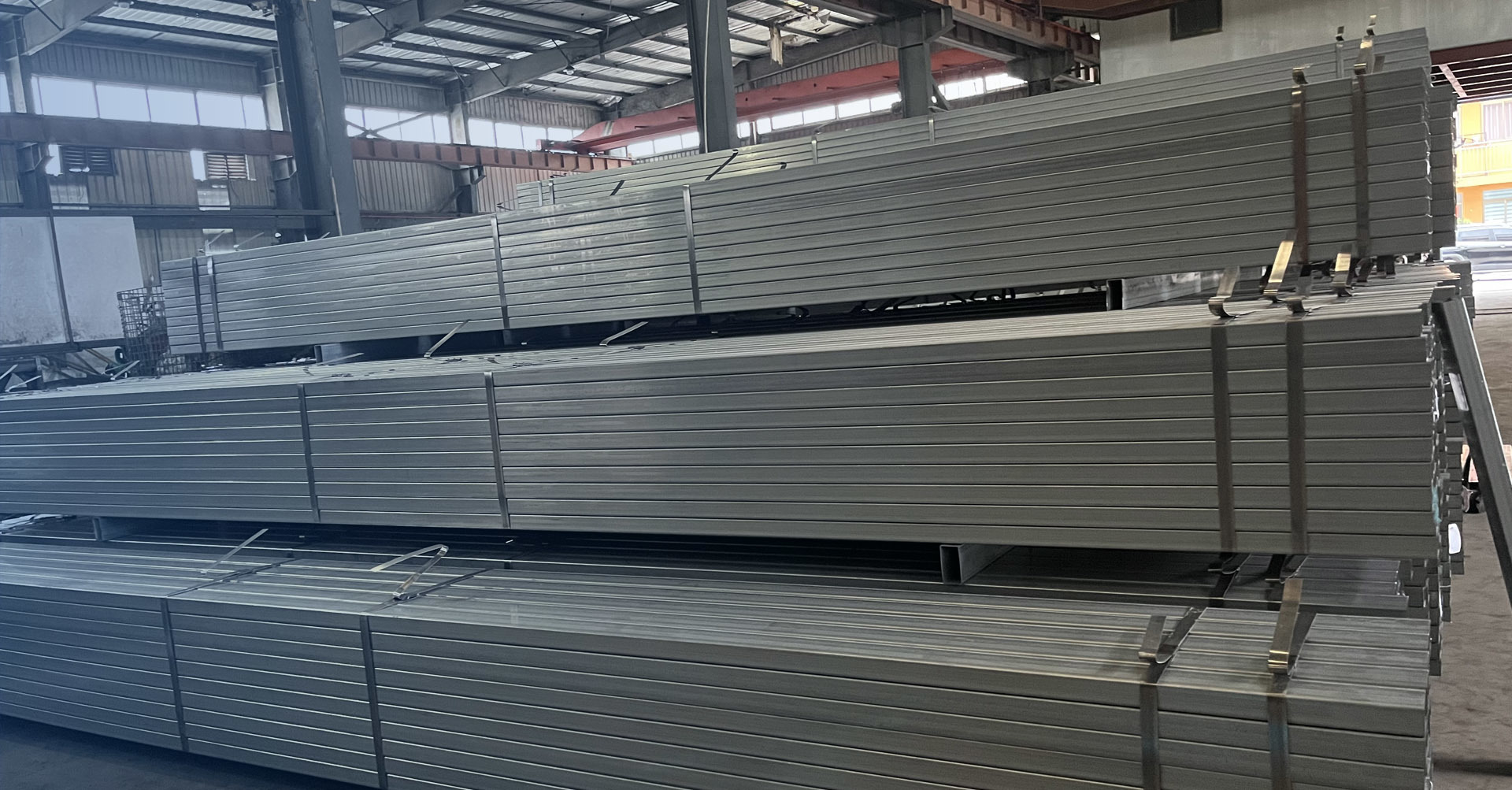

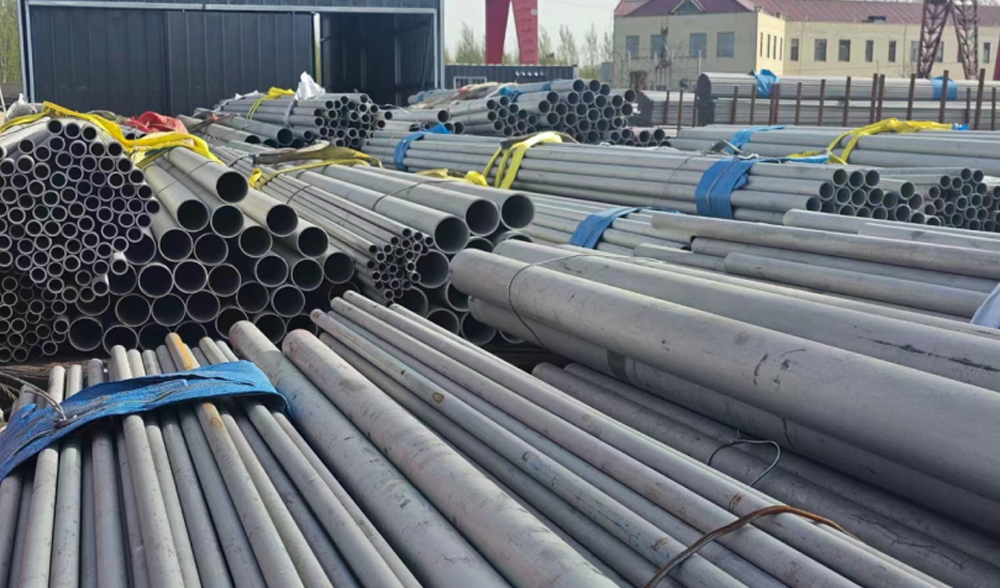

Tangshan Zhefeng Stainless Steel Co., Ltd. was established in 2006, located in Fengnan District, Tangshan City, with a registered capital of 10 million yuan (fully paid in). This supplier sells 10000 tons of stainless steel annually and is a strong enterprise specializing in the sales, processing, and warehousing logistics of stainless steel in North China. This supplier is a distributor of Zhejiang Baofeng, Zhongwu Steel Pipe, Dongfang Special Steel, and Taiyuan Iron and Steel. They have participated in the supply of steel for key engineering projects in North China multiple times and have established long-term good cooperative relationships with customers. The company's main business is selling stainless steel pipes, stainless steel plates, hot-rolled coils, and stainless steel profiles all year round.